Tailored CNC Milling Services For Precision Prototyping In Low Volumes

In the aerospace, medical, electronic, and automotive industries, businesses are adopting custom CNC milling for low-volume, high-precision prototyping. It greatly simplifies product development cycles while maintaining strict functional and tolerance standards for prototypes compared to traditional machining methods. Owing to the ever-increasing need for specialized parts, CNC precision machining now serves as a pivotal asset for firms aiming to transform their designs into products, as it provides an efficient resolution to the gap between a conceptual design and a market-ready product.

In this article, we discuss the importance of custom CNC milling in low-volume prototyping and its high-precision benefits, including crucial factors for B2B purchasers around dependable engineering firms.

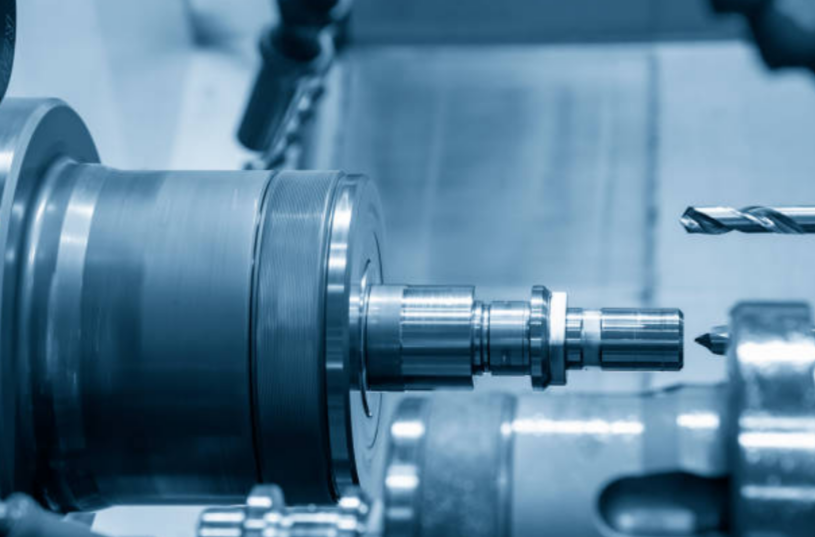

The Importance of Custom CNC Milling in Prototyping

Custom CNC milling as a form of subtractive manufacturing involves a custom CNC machine that performs the CNC milling process to precision specifications, meaning that it removes materials from a workpiece to create parts of the desired shapes. It differs from other manufacturing processes with a low-volume focus where producing small quantities, as in one-off to a few hundred units, aids in evaluative design, performance testing, and iterative functionality refining.

In sectors such as surgical instruments, aerospace components, or detailed electronic fittings, CNC precision machining makes it possible to manufacture components with tolerances of up to ±0.005mm. The precision matters for intricate geometries, surface finishes, and components that need to precisely work and fit with other systems.

Prototyping also makes it easier to make changes to a design without a business being locked into expensive mass production tooling. This can be a critical competitive edge when entering new regions or when responding to shifting customer expectations.

Benefits of CNC Precision Machining for Lower Volume Projects

The advantages of CNC precision machining for high-value, low-volume prototypes are not limited to precision alone. It is possible to gain a distinct blend of operational benefits and precisely engineered project capabilities that increase overall efficiency.

Enhanced Accuracy and Precision with High Repeatability

The accuracy of modern CNC milling machines when paired with experienced machinists and up-to-date CAD/CAM software is their ability to execute intricate designs with exceptional precision. This makes it possible for every prototype to be manufactured to the same design tolerances, thus minimizing the chances of errors during subsequent production phases.

Flexibility with Different Materials

Custom CNC milling supports a variety of materials such as plastics, brass, aluminum, copper, stainless steel, titanium, and even sophisticated plastic composites. With this level of versatility, engineers are able to assess prototypes and production pieces in the same material, ensuring thorough evaluations of performance.

Cost Effectiveness for Limited Quantity Production

CNC milling might not achieve the same level of economies of scale as the per unit price for a higher volume of parts, but it eliminates the costs incurred from injection mold tooling or large-scale stamping dies. For companies that only need a small quantity, the cost for each part becomes feasible, particularly with the faster iteration cycles.

Quicker Market Availability

Custom CNC milling speeds up the process of developing new parts and products by streamlining prototype development and eliminating the need for extensive tooling. In business-to-business markets, having a fully functional prototype ready the earliest often means winning contracts and business opportunities.

The Most Important Factors to Assess in a CNC Precision Machining Partner

For low-volume, high-precision prototyping, the CNC precision machining partner with the best price may not always be the best choice. The following criteria are indispensable to achieve the most valuable results.

Specialized Knowledge of Intricate Shapes

Low-volume prototypes sometimes require intricate complex designs. In this case, look for machining partners that multi-axis mill, create complex cavities, do intricate part machining as well as advanced 4-axis and 5-axis milling. These advanced 4-axis and 5-axis milling capable partners offer increased design flexibility along with fewer setups thus increasing accuracy and efficiency.

Compliance Verification and Audit Processes

Precision machining requires strict processes for verifying and inspecting integrals and excess. These should include coordinate measuring machines (CMM), surface roughness testers, and comprehensive documentation processes. Compliance verification of each part’s conformance needs independent cross verification and thus repeatable processes. A capable machining joker should be equipped with all these capabilities.

Engineering Engagement and Prototyping Started

Low volume machining projects and prototypes performed by a shopper should ensure that engineer and machinist collaboration happens early. This ensures robust design and protects function to machining balance. A Partner that offers design for manufacturability (DFM) input should be able to perform better priced prototypes and streamlined processes.

Responsiveness and Cycle Time

Low-volume projects, according to expectations, incur strict response deadlines. This need requires a partner that will not compromise on quality wakes while catering for urgent or compressed lead times. Ensuring that delivery milestones are met requires prototypes after due dates.

Uses of Custom CNC Milling in High-Precision Prototyping

Custom CNC milling is indispensable in working with high-precision and high-reliability prototypes in different fields of industrial innovation and technology. Here are some examples of use cases.

Parts of Aerospace

Aerospace prototypes are turbine blades, brackets, and housings which undergo extreme temperatures, vibrations, and rotational mechanical stresses. CNC precision machining enables the manufacture of these parts with a high degree of accuracy and repeatability.

Applicator of Medical Devices

Every Medical Device Prototype like surgical instruments and orthopedic implants require CNC precision biocompatibility for the implants so they operate like their production mates and perform flawlessly for the required operational regulations.

Electronics and Instruments

Precision CNC milling is also important in the electronics, for the production of casings, sinks and housings which are usually crucial for densely packed devices.

Prototypes of Automotive

Custom CNC milling is advantageous in the testing of intake manifolds and gearbox housing for performance vehicles and advanced automotive systems. Prototypes are testable in practical situations before the mass production of the model.

The Role of CNC Precision Machining in Driving Innovation

The connection between custom CNC milling and innovation is made clear by the efficiency of engineers in transforming CAD models into physical components. The speed at which one is able to prototype is beneficial in the following ways:

- Ramped iterative design – Improving and refining features after functionality evaluations.

- Risk reduction – Addressing potential design issues ahead of time in low-cost testing.

- Enhanced customization – Addressing specific needs of the project without expensive retooling.

From the standpoint of B2B purchasers, innovation sharpens financial returns and enhances product value. Businesses also enhance financial returns while exploring new opportunities in the market.

Read Also: Transforming the Customer Experience with Custom LCD Displays

Future Expectations of Custom CNC Milling in Prototyping

The role of CNC Milling in custom low-volume high precision prototyping is further expected to be expanded with the following:

- Additive Manufacturing – CNC milling is expected to be more flexible through the merging of additive manufacturing.

- Automation and AI – Improvement in efficiency by reduction in time consuming processes such as improving setup, and optimizing toolpaths.

- Machining – The ability to machine high strength alloys and composites makes next-generation products possible.

Enhanced innovation accessibility is going to grant businesses unprecedented levels of control over their prototyping, enabling customization for demanding industries.

Conclusion

Custom CNC milling is redefining business strategies when it comes to low-volume and high precision prototyping. With CNC precision machining, it is now possible to create fully functional and accurate prototypes that are both durable and cost-efficient when compared to the financial and time investment needed for mass production tooling. Sectors such as aerospace, medical devices, electronics, and automotive are now able to leverage this technology for the precision and agility that is crucial for transforming ideas into physical prototypes, testing them in real-world scenarios, and fine-tuning them for peak efficiency.

In the context of turning to a machining partner, the business’s abilities, quality control, material capabilities, and flexibility are all critical factors that drive success in the CNC machining projects. With the advancements in CNC technology, the capabilities to foster innovation and expedite the pace of product development will continue to grow in the foreseeable future, which proves beneficial for enterprises all over the globe.